Manufacturing reliability separates industry leaders from those constantly firefighting quality issues and delivery delays. Commercial applications demand parts that meet exact specifications every time, whether producing automotive components, industrial equipment, or construction materials. The gap between adequate and exceptional production capability often determines long-term business success.

These strategies apply across diverse manufacturing sectors, from precision machining to metal fabrication. Organizations that systematically implement these approaches create predictable outcomes while maintaining competitive pricing and delivery schedules.

Establish Comprehensive Quality Control Protocols

Quality control systems form the foundation of reliable parts production. Rather than inspecting finished products alone, effective protocols monitor critical parameters throughout the entire manufacturing process. This proactive approach identifies variations before they compound into defects.

Statistical process control provides real-time visibility into production trends. When measurements begin drifting from target specifications, operators receive immediate alerts to make adjustments. This prevents entire production runs from falling outside acceptable tolerances. Automated inspection technologies enhance human oversight by detecting subtle variations that might escape visual examination.

Documentation systems track every component through production stages, creating accountability and enabling root cause analysis when issues arise. Digital quality management platforms connect inspection data with specific machines, operators, and material lots. This traceability proves invaluable when investigating customer concerns or pursuing continuous improvement initiatives.

Invest in Equipment Maintenance and Calibration

Production equipment reliability directly influences output consistency. Well-maintained machinery produces parts within specification while minimizing unexpected downtime. Preventive maintenance schedules based on manufacturer recommendations and historical performance data keep equipment operating at peak capability.

Calibration programs ensure that measuring instruments provide accurate readings. A micrometer displaying incorrect measurements leads operators to accept out-of-specification parts or reject acceptable components. Both scenarios create costly problems. Regular calibration by certified technicians maintains measurement integrity across the production environment.

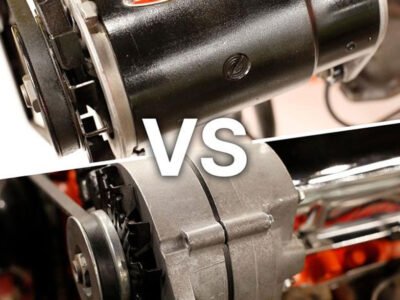

Equipment upgrades deserve consideration when older machinery struggles to meet modern precision requirements or throughput demands. Technologies like CNC machining centers and laser cutting systems deliver repeatability that manual operations cannot match. These investments pay dividends through reduced scrap rates and increased production capacity.

Develop Robust Supplier Relationships

Material quality significantly impacts finished part reliability. Establishing partnerships with suppliers who understand your requirements and maintain consistent quality standards reduces incoming material variations. Single-source strategies for critical materials minimize the variables that can affect production outcomes.

Incoming inspection protocols verify that materials meet specifications before entering production. Testing procedures might include dimensional checks, material composition analysis, or mechanical property verification. Catching substandard materials at receipt prevents them from consuming production resources or reaching customers.

Supplier performance metrics create accountability while identifying improvement opportunities. Tracking defect rates, on-time delivery, and responsiveness to quality concerns informs sourcing decisions. Strong supplier relationships built on clear communication and mutual success drive long-term reliability improvements.

Implement Standard Operating Procedures

Documented procedures ensure consistent production methods regardless of which operator runs a particular job. Standard operating procedures (SOPs) capture best practices developed through experience and engineering analysis. They eliminate guesswork by providing step-by-step instructions for setup, operation, and inspection activities.

Training programs built around SOPs accelerate new employee proficiency while reinforcing proper techniques for experienced workers. Regular review sessions keep procedures current as processes evolve or equipment changes. Visual aids like photos and diagrams supplement written instructions to improve comprehension and retention.

Process validation confirms that SOPs produce intended results under various conditions. This testing phase identifies potential failure modes and verifies that specifications remain achievable across normal production variations. Validated processes provide confidence that following documented procedures will consistently yield quality parts.

Utilize Advanced Manufacturing Technologies

Modern manufacturing technologies enhance production reliability through precision and repeatability that exceed manual capabilities. Computer-aided manufacturing systems execute complex operations with consistent accuracy, reducing human error while improving throughput. Whether producing metal roofing in Utah or precision aerospace components, advanced equipment delivers measurable quality improvements.

Automation solutions handle repetitive tasks with unwavering consistency. Robotic material handling eliminates variations introduced by manual positioning. Automated inspection systems measure critical features at rates impossible for human operators while maintaining objective standards. These technologies free skilled workers to focus on complex problem-solving and process optimization.

Data collection systems integrated with production equipment provide insights into process performance trends. Analytics platforms identify correlations between operating parameters and quality outcomes, enabling targeted improvements. This intelligence transforms manufacturing from reactive troubleshooting to proactive optimization.

Commercial parts production demands systematic approaches that address every factor influencing quality and consistency. Organizations implementing these five strategies position themselves for sustainable competitive advantages through superior reliability, customer satisfaction, and operational efficiency.