In the construction industry, time is money. Every hour a piece of machinery sits idle can translate into significant losses, delayed projects, and frustrated teams. One of the most effective ways to prevent downtime is through proactive and consistent maintenance of heavy construction equipment. From bulldozers and excavators to cranes and loaders, proper care ensures that your machinery operates efficiently, safely, and reliably.

1. Establish a Routine Maintenance Schedule

The first step in preventing equipment failure is developing a comprehensive maintenance schedule. Regular inspections and servicing help identify small issues before they become costly problems. Daily, weekly, and monthly checks should cover key areas such as fluid levels, hydraulic systems, engine performance, tires, tracks, and electrical components. For larger machinery, quarterly or annual preventive maintenance programs can include detailed inspections, component replacements, and system calibrations. By adhering to a consistent schedule, you not only extend the lifespan of your machinery but also reduce the risk of unexpected breakdowns.

2. Monitor Fluids and Lubrication

Fluids are the lifeblood of construction equipment. Engines, hydraulics, transmissions, and cooling systems all rely on proper lubrication and fluid levels to function efficiently. Dirty or low fluids can lead to overheating, excessive wear, and complete system failure. It’s essential to regularly check oil, coolant, hydraulic fluid, and transmission fluids, replacing them according to manufacturer recommendations. Lubricating moving parts like joints, pins, and bearings reduces friction and prevents premature wear. Using high-quality lubricants and fluids not only improves performance but also minimizes the risk of mechanical failure.

3. Train Operators for Proper Use

Even the best-maintained equipment can fail if used improperly. Training operators on the correct handling and operation of machinery is a crucial component of maintenance strategy. Proper techniques, such as avoiding overloading, using the right attachments, and performing regular checks before and after shifts, can significantly reduce wear and tear. Educating operators about warning signs of mechanical issues, such as unusual noises, vibrations, or leaks, ensures problems are identified and addressed early, preventing costly downtime.

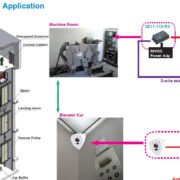

4. Implement Predictive Maintenance Technology

Modern construction companies are increasingly turning to technology to prevent equipment failure. Predictive maintenance uses sensors and telematics to monitor machinery in real-time, tracking engine performance, hydraulic pressure, temperature, and other critical parameters. Data collected can predict when a component is likely to fail, allowing maintenance teams to schedule repairs before a breakdown occurs. This approach not only reduces downtime but also optimizes maintenance costs by focusing efforts on equipment that truly needs attention rather than performing routine work unnecessarily.

5. Keep Equipment Clean and Protected

Construction sites are harsh environments. Dust, mud, debris, and extreme weather can take a toll on machinery. Regular cleaning of equipment prevents abrasive materials from damaging critical components. Additionally, protecting equipment with covers, shelters, or designated storage areas minimizes exposure to elements that accelerate wear. Attention to cleanliness is especially important for hydraulic systems, air filters, and cooling systems, as contamination can lead to significant mechanical issues.

6. Maintain Proper Tire and Track Care

For mobile construction equipment, tires and tracks are critical to safe and efficient operation. Overinflated, underinflated, or worn tires increase the risk of accidents and reduce fuel efficiency. Tracks on bulldozers and excavators need regular tension checks and inspections for damage. Replacing or repairing damaged tires and tracks promptly prevents secondary mechanical failures and keeps projects on schedule.

7. Plan for Safe and Efficient Transportation

Sometimes, maintenance requires moving large machinery offsite or between projects. Using specialized equipment like a Lowboy trailer ensures safe transportation without causing damage to your machinery. Proper transportation is part of a broader maintenance strategy because it prevents structural stress and wear that can occur during improper handling.

8. Keep Detailed Records

Finally, documenting all maintenance activities is essential. Detailed records of inspections, repairs, and replacements allow teams to track equipment health over time, identify recurring issues, and plan for future maintenance needs. Well-kept records improve budgeting, scheduling, and compliance with manufacturer warranties and safety regulations.

In Conclusion

Preventing downtime in construction is not just about fixing problems—it’s about proactive planning, regular maintenance, and proper operation. By establishing a structured maintenance schedule, monitoring fluids, training operators, leveraging predictive technology, protecting equipment, and keeping thorough records, construction companies can maximize machinery uptime, reduce repair costs, and keep projects on track. Investing in maintenance is investing in productivity, safety, and long-term success. After all, well-maintained machines don’t just work—they perform reliably when you need them the most.

![Why Everyone's Talking About Lufanest: Your Essential Guide [2025]](https://homechefdaily.com/wp-content/uploads/2025/09/Lufanest-400x225.jpg)